Do you need to complete improvement projects to improve quality, flow, delivery precision, efficiency or productivity? Then Six Sigma can be recommended. But what exactly is Six Sigma and how do you use it in your improvement projects?

Six Sigma (6S) is a leadership initiative originally developed by American Motorola. 6S includes the standardized approach (DMAIC method), standardized documentation and standardized roles for implementation of improvement projects.

This standardization has a number of advantages, such as:

Experience shows the prerequisite for successful use of Six Sigma is a practical and pragmatic application of method and tools.

Six Sigma is an important component of the company’s Business Improvement System (BIS). BIS is the system that will ensure continuous work on internal business development to deliver in line with short term and long-term goals.

Another key component is the day-to-day continuous improvement structures in the line organization.

A third component is the structures the business has for developing strategic action plans that identify, among other things, improvement and change initiatives implemented through the aforementioned components.

In addition to the project manager, Six Sigma projects also appoint a project supervisor. The project supervisor should both be a support, but also a driver for the project. The supervisor shall ensure that the interests of the customers and the business are safeguarded. The supervisor must also ensure that the project has the best possible communication with the stakeholders.

Project supervisors should be carefully selected persons who are given in-depth training in methods and tools. The training given qualifies for the competence level “Black Belt”. A Black Belt can also be the project manager for more demanding improvement projects. We will not go into the roles of 6S in this article any further. You can learn more about this in the book Six Sigma Leadership Handbook.

We will now briefly introduce the DMAIC method so that it can be used to solve process problems. The purpose is to assist you in considering Six Sigma as an alternative for you and your business.

DMAIC is a method for solving all types of process problems and product problems that require causal analysis. The method has been named from the initial letters of the method’s phases: Define, Measure, Analyze, Improve and Control.

Let’s take a closer look at these phases.

The purpose of this phase is to develop a clear future state for the project. The future state is described in a standardized project charter template.

The following is done in this phase:

Key tools in this phase are:

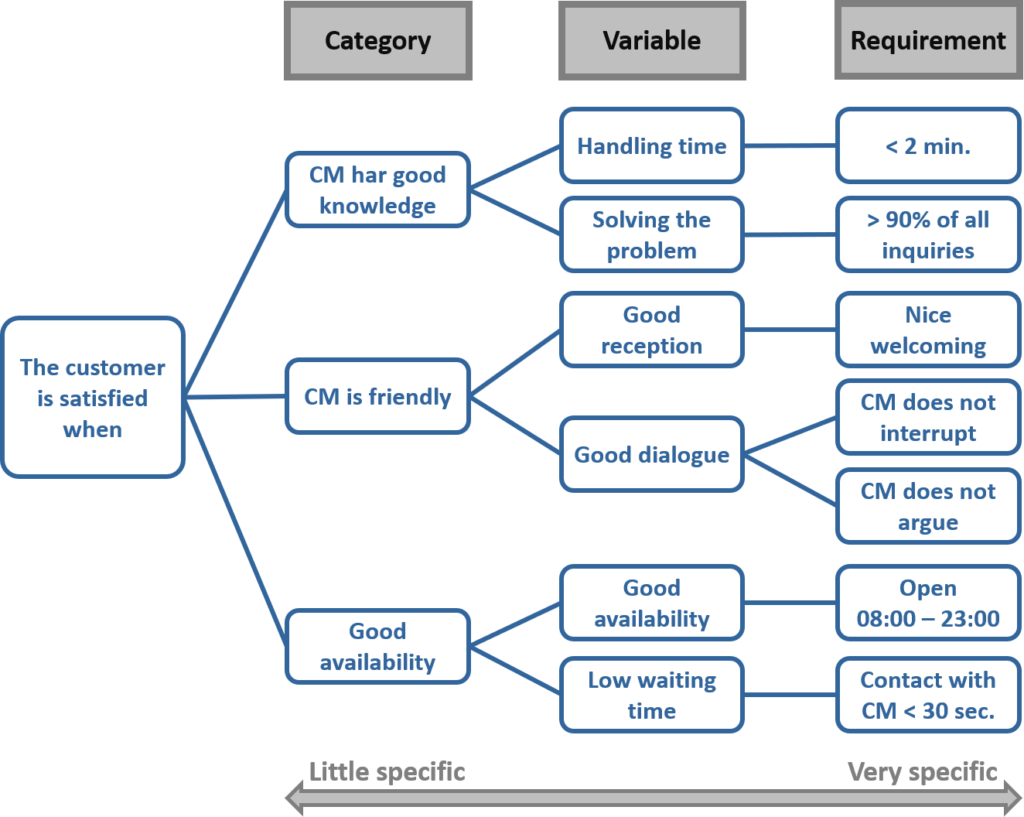

The figure below illustrates a CTQ tree for a customer service process. CM = Customer Manager. Among other things, the tree shows that the customer(s) is satisfied when the requirement for processing time of less than 2 minutes is satisfied.

During the measurement and analysis phase, the team will identify the presumed most important root causes for the failure to meet priority requirements.

To ensure identification of the right root causes, it is crucial to involve the people who really understand what is going on in the process.

The following tools can be used in this phase:

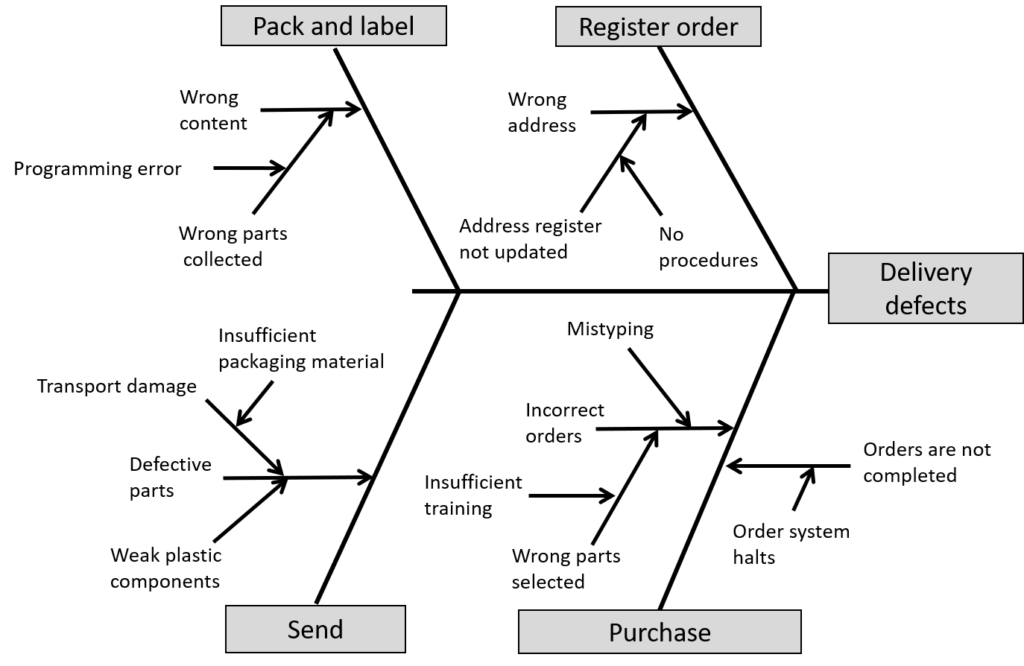

The figure below shows a fish bone diagram. In this case, the chart visualizes the causal relationships that explains why there are errors in customer deliveries. In this case, the reasons are grouped under the categories labeling, packaging, order registration, purchasing and logistics. The first arrow in the chain of arrows indicates the root cause of “Delivery defects”. For example, the figure shows that the cause “No procedures” (for updating the address register) is a possible root cause of errors in deliveries.

The measurement and analysis phase ends when the assumed root causes of poor performance are identified. A corresponding argument is required for the choice of root causes. The arguments should be based on data and/or process analysis.

In the Improve phase, the team will first identify alternative solutions to each of the priority root causes. Alternatives should be considered in the short and long term; solutions should be considered that do not require funding beyond the existing budget; and solutions that require investment.

For all alternatives, the associated solution risk, potential for improvement, gains, complexity and implementation time are assessed. Based on insight, solutions are recommended and selected. If possible, solutions should be tested on a smaller scale before full implementation.

Important tools in the Improve phase are tools for prioritization and risk analysis. Other tools that are also relevant are the canoe model, creativity techniques such as Triz and experimental design.

The last phase of the DMAIC is the Control phase. In this phase, the team will document the improved performance of the priority variables. If possible and appropriate, the associated financial gains must also be documented.

To ensure lasting improved performance, new responsibilities must be formalized and process descriptions, training systems and measurement systems updated. A formal handover of solutions and remaining activities will also be carried out to the line organization’s process and system owners.

Last, but not least, the team in the control phase should describe and communicate results that can be reused by others. After updating the standard Six Sigma project report (storyboard) and formal approval of the project’s deliveries, appropriate marking of successful completion should be provided.

We have now provided you with an introduction to 6S as a standard for improvement projects. Want to know more about how to implement 6S and other key components of a comprehensive business improvement system? Download our guideline on how to implement a business improvement system by clicking the button below.